Thermoforming equipment is divided into manual, semi-automatic and fully automatic.

All operations in manual equipment, such as clamping, heating, evacuation, cooling, demoulding, etc., are adjusted manually; All operations in semi-automatic equipment are automatically completed by the equipment according to preset conditions and procedures, except that clamping and demoulding need to be completed manually; All operations in the fully automatic equipment are completely carried out automatically by the equipment.

Basic process of vacuum thermoforming machine: heating / forming – cooling / punching / stacking

Among them, molding is the most important and complex. Thermoforming is mostly carried out on the forming machine, which varies greatly with different thermoforming methods. All kinds of molding machines do not have to complete the above four processes, which can be selected according to the actual production needs. The main parameters of thermoforming machine are usually the feeding size of heating temperature and the vacuum time difference of forming.

1. Heating

The heating system heats the plate (sheet) to the temperature required for forming regularly and at a constant temperature, so that the material becomes a high elastic state and ensures the smooth progress of the next forming process.

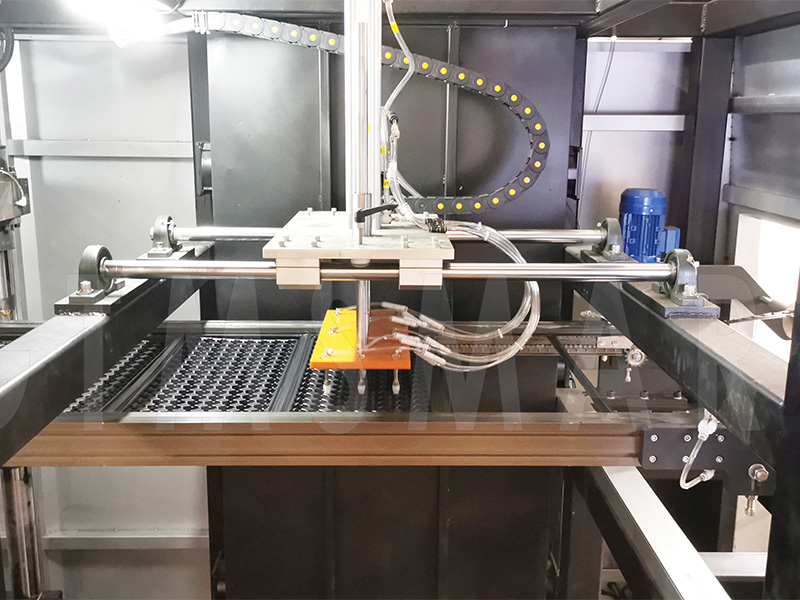

2. Simultaneous molding and cooling

The process of molding the heated and softened plate (sheet) into the required shape through the mold and positive and negative air pressure device, and cooling and setting at the same time.

3. Cutting

The formed product is cut into a single product by laser knife or hardware knife.

4. Stacking

Stack the formed products together.

GTMSMART has a series of perfect thermoforming machines, such as disposable cup thermoforming machine, plastic food container thermoforming machine, seedling tray thermoforming machine, etc. We always follow the standardized rules and strict production process to save time and cost for both parties and bring maximum benefits to you.

Post time: May-06-2022