A very good way to make products from plastics is by thermoforming machine, which is the process of heating a huge plastic sheet to a very high temperature and then cooling it in the required format. Thermoplastics are an increasing range and diversity of types. Our plastic thermoforming machine can produce different plastics, so there are many different types of products produced by our machine. Let’s explore the range of materials available and discuss how to adapt them to different applications and industries.

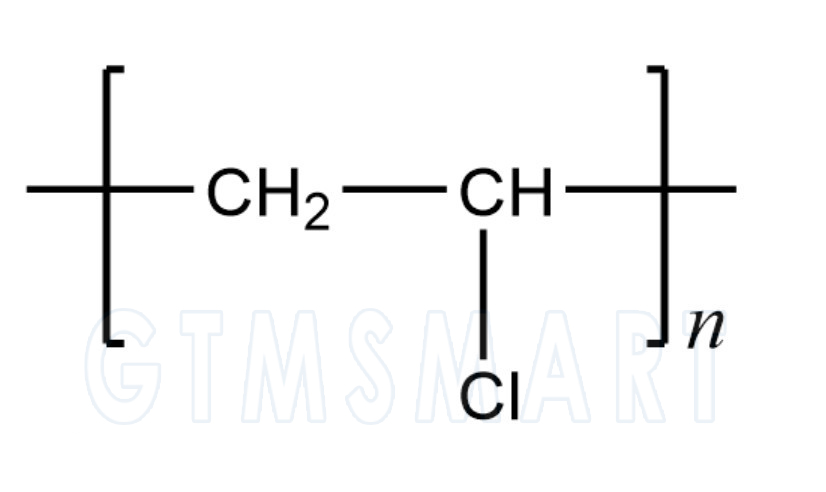

PVC(Polyvinyl chloride)

PVC is a familiar name for many people. This plastic has a strong hard structure, which is an ideal rigid plastic that can withstand extreme temperatures and impacts. Its low cost also makes it attractive to the company. Products made of PVC include packaging and shipping pallets, shell materials, wires and cables and other telecommunications products.

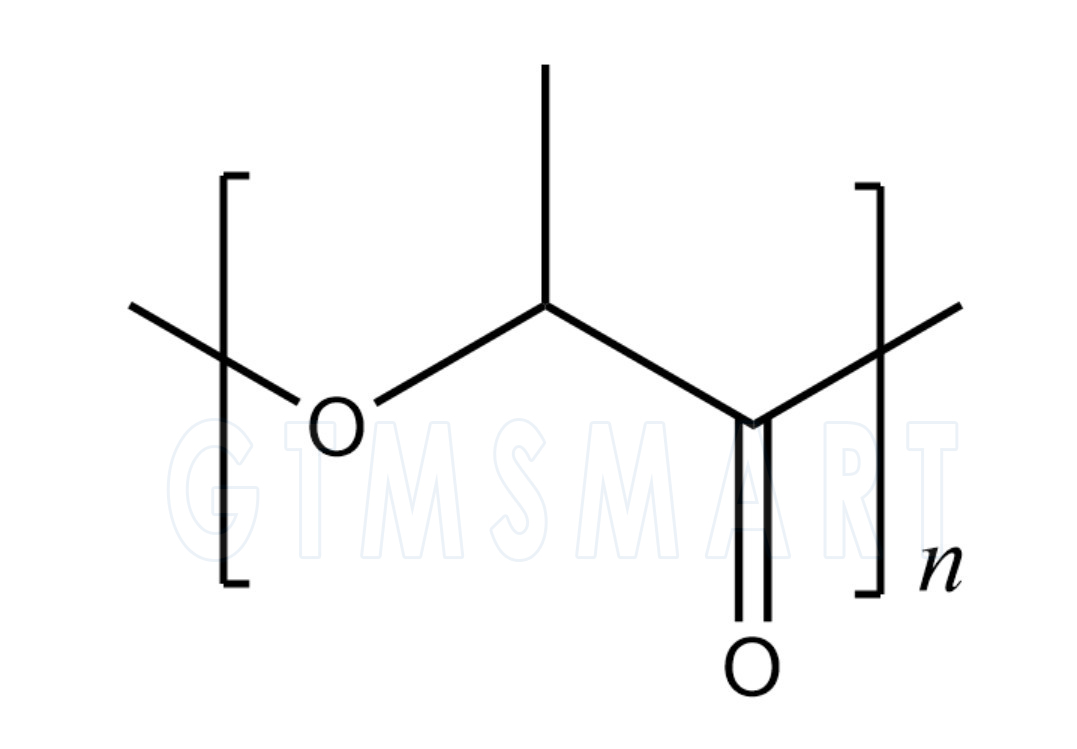

PLA(Polylactic acid)

PLA is a new biodegradable material, which is made of starch raw materials proposed by renewable plant resources (such as corn). It’s absolutely harmless to human body, which makes polylactic acid have unique advantages in the field of disposable tableware, food packaging materials and other disposable products.

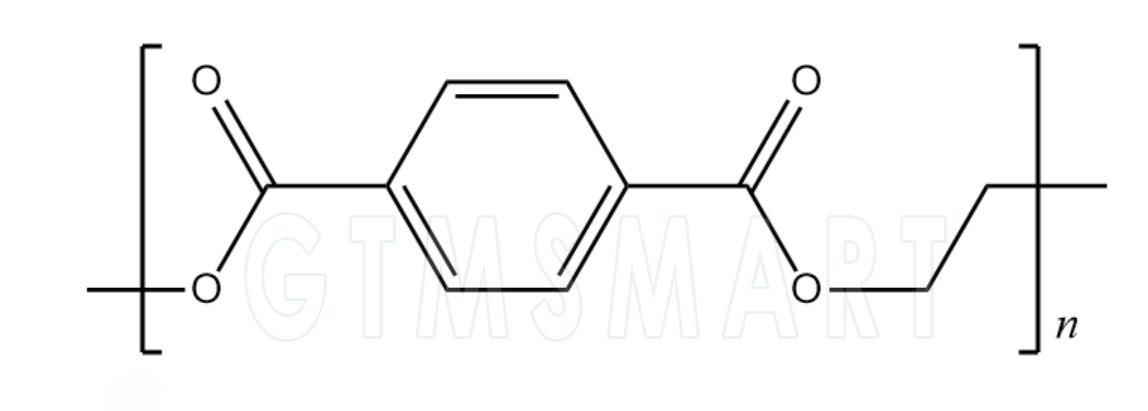

PET(Polyethylene glycol terephthalate)

PET is a milky white or light yellow highly crystalline polymer with smooth and shiny surface. It has the largest toughness among thermoplastics: good electrical insulation, less affected by temperature, but poor corona resistance. This plastic is also one of the most recyclable plastics.

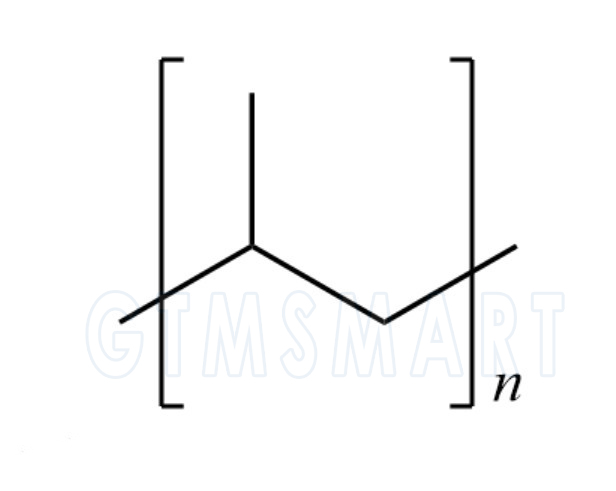

PP(Polypropylene)

PP is a kind of thermoplastic synthetic resin with excellent performance. It is a colorless and translucent thermoplastic light general-purpose plastic. It is easy to customize and dye, light weight and not easy to break. However, it is not as UV-resistant as other thermoplastics. It is widely used in various containers, furniture, packaging materials and medical equipment.

HIPS(High impact polystyrene)

HIPS has the dimensional stability of general purpose polystyrene (GPPS), and has better impact strength and rigidity. The transparency and fragility of this plastic make it an ideal plastic for protective packaging. It is easy to manufacture and low-cost. The largest single application of hips is packaging, especially in the food industry, with more than 30% of the world’s consumption.

We are happy to help you find the right products in GTM thermoforming machine, GTM has a professional technical team determined to research, development, and production of high efficiency, energy saving and highly automated plastic sheet extrusion and molding related equipment.

PLC Pressure Thermoforming Machine With Three Stations

Plastic Cup Thermoforming Machine

Hydraulic Servo Plastic Cup Thermoforming Machine

Plastic Vacuum Forming Machine

PLC Automatic PP PVC Plastic Vacuum Forming Machine

Plastic Flower Pot Thermoforming Machine

Automatic Hydraulic Plastic Flower Pot Thermoforming Machine

Post time: Oct-18-2021