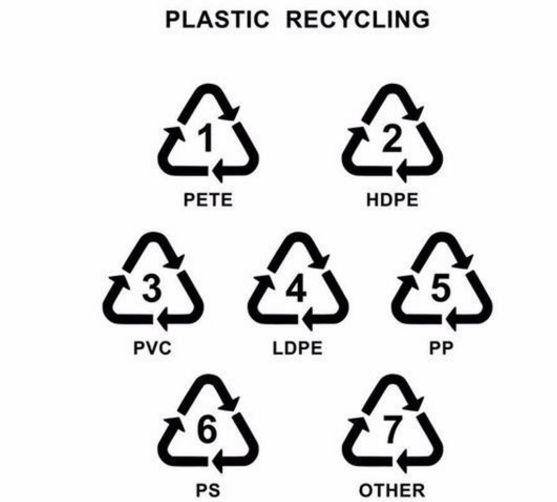

At the bottom of the disposable plastic cup or the cup cover, there is usually a triangle recycling label with an arrow, ranging from 1 to 7. Different numbers represent different properties and uses of plastic materials.

Let’s take a look:

“1″ – PET (polyethylene terephthalate)

More common in mineral water bottles and beverage bottles. This material is heat-resistant 70 and can be filled with normal temperature water in a short time. It cannot suitable for acid-base drinks or high-temperature liquids, and it is not suitable for exposure to the sun, otherwise it will produce toxic substances harmful to human body.

“2″ – HDPE (high density polyethylene). Commonly used in medicine bottles, shower gel packaging, not suitable for water cups, etc.

“3″ – PVC (polyvinyl chloride). It has excellent plasticity and low price, so it is widely used. It can only be heat-resistant to 81 °C, and it is easy to produce bad substances at high temperature. It is less used for packaging food.

“4″ – LDPE (low density polyethylene). Cling film and plastic film are all made of this material. The heat resistance is not strong, and hot melting will occur when it exceeds 110 ℃.

“5″ – PP (polypropylene). It has good thermal stability and insulation, and is safe and harmless to human body. The product can be sterilized at a temperature above 100, does not deform at 150 under the action of external force, and has no pressure in boiling water. Common soymilk bottle, yogurt bottle, fruit juice beverage bottle, microwave oven lunch box. The melting point is as high as 167 ℃. It is the only plastic box that can be put into the microwave oven and can be reused after careful cleaning. It should be noted that for some microwave oven lunch boxes, the box body is made of No. 5 PP, but the box cover is made of No. 1 PE. Because PE cannot withstand high temperature, it cannot be put into the microwave oven together with the box body.

“6″ – PS (polystyrene). The plastic cup made of PS is extremely brittle and resistant to low temperature. It can not be used in high temperature, strong acid and strong alkali environment.

“7″ – PC and others. PC is mostly used to make milk bottles, space cups, etc.

Therefore, when drinking hot drinks, it is best to pay attention to the symbols on the cup cover, and try not to use “PS” logo or “No. 6″ plastic material to make cup cover and tableware.

Plastic Cup Thermoforming Machine Series

HEY11 Hydraulic Servo Plastic Cup Thermoforming Machine

Cup Making Machine Feature

-Utilize hydraulic system and electrical technology control for servo stretching. It’s a high price ratio machine which was developed base on customer’s market demand.

-The whole plastic cup making machine is controlled by hydraulic and servo, with inverter feeding, hydraulic driven system, servo stretching, these make it has stable operation and finish product with high quality.

HEY12 Biodegradable PLA Disposable Plastic Cup Making Machine

Cup Making Machine Application

The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers, etc) with thermoplastic sheets, such as PP, PET, PE, PS, HIPS, PLA,etc.

The cup making thermoforming machine independently developed by GTMSMAMRT machinery has a mature production line, stable production capacity, high-quality skills, CNC R & D team and perfect after-sales service network, which can provide you with a one-stop solution.

Post time: May-27-2022