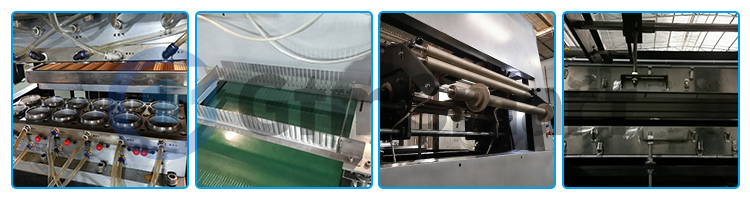

The whole production line of disposable plastic cups mainly includes: cup making machine, sheet machine, mixer, crusher, air compressor, cup stacking machine, mold, color printing machine, packaging machine, manipulator, etc.

Among them, the color printing machine is used for color printing Cup, which is generally used for milk tea cup and fruit juice beverage cup. The ordinary disposable water cup does not need the color printing machine. The packaging machine automatically packs supermarket cups, which is mainly hygienic, fast and labor-saving. If it only makes market cups, it does not need to be configured. The manipulator aims at the products that cannot be used by the cup folding machine, such as fresh-keeping box, fast-food box, etc. Other machines are standard and must be equipped with.

Cup making machine: It is the main machine for producing disposable plastic cups. It can produce various products with molds, such as disposable plastic cups, jelly cups, disposable plastic bowls, soybean milk cups, fast food packaging bowls, etc. For different products, the corresponding mold needs to be replaced.

Mold: It is installed on the cup making machine and is specially customized according to the product. Usually the first mock exam is a product of a set of molds. When a product has the same caliber, capacity and height, the mould parts can be replaced, so that the mould can be used for a multi purpose mold, and the cost is greatly saved.

Sheet machine: It is used to process the raw materials of disposable plastic cups. The plastic particles are made into sheets, rolled into barrels for standby, and then transported to the cup machine for heating and forming into plastic cups.

Crusher: There will be some leftover materials left in production, which can be crushed into particles and then continue to be used. They are not waste.

Mixer: The leftover material is crushed and mixed with the brand-new granular material in the mixer, and then used again.

Air compressor: The cup making machine forms the required products by forcing the sheet close to the surface of the mold cavity through air pressure, so an air compressor is needed to produce air pressure.

Cup stacking machine: Automatic folding of disposable plastic cups eliminates the problems of slow manual cup folding, unsanitary, increasing labor cost and so on.

Packaging machine: The outer sealing plastic bag of supermarket cup is automatically packaged by the packaging machine. After the cup stacking machine completes the folding, it is automatically counted, packaged and sealed by the packaging machine.

Manipulator: The cup making machine can not only make cups, but also make lunch boxes, fresh-keeping boxes and other products in line with the forming principle. For the case that the cup stacking machine cannot be overlapped, the manipulator can be used to grasp the overlapped cup.

Color printing machine: Print some patterns and words for milk tea cups, some packaged beverage cups, yogurt cups, etc.

Automatic feeding machine: automatically add plastic raw materials to the sheet machine, saving time and labor.

Not all the above equipment are used, but are configured according to the actual production needs.

Post time: Mar-31-2022