With the improvement of people’s quality of life, the acceleration of the pace of life and the rapid development of tourism, eating abroad has become more and more common. The consumption of disposable paper cups and plastic cups is increasing day by day, and the disposable products industry is booming. Many enterprises are optimistic about this market and have invested a lot of human, material and financial resources in the development of disposable tableware. In order to avoid unnecessary losses and repeated investment caused by enterprise investment, let’s talk about the understanding and selection of paper cup and paper cup forming machine today. So that enterprises interested in investing in paper cup production have a comprehensive and systematic understanding of the production process, use, function and market potential of paper cup and machine make cups paper.

Structural design of paper cup

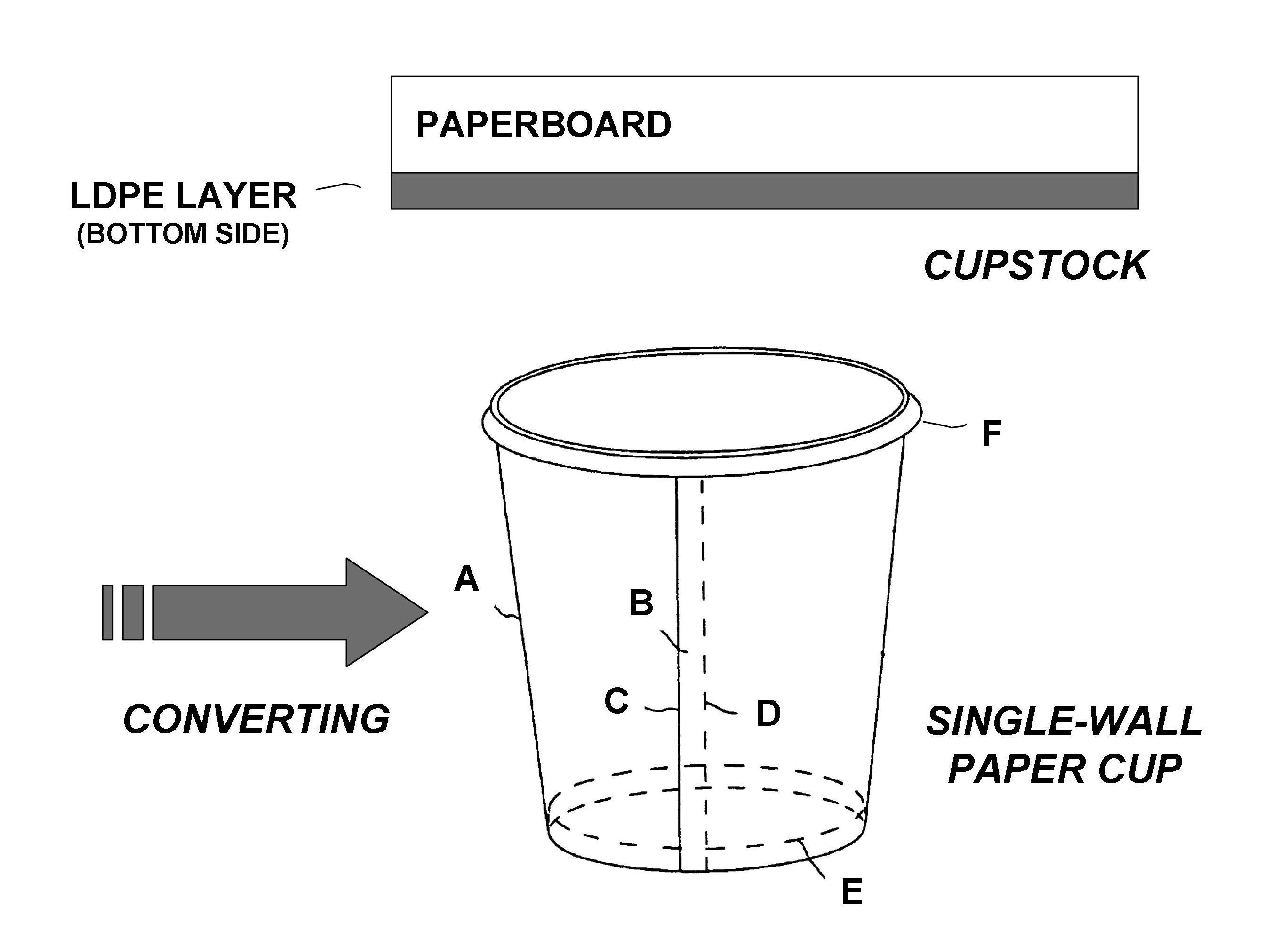

At present, most paper cups are made of coated cardboard or cup holders. This paper cup can be single wall or double wall. The barrier coating is usually made from PE, which is extruded or laminated on the paperboard. The cup comprises a paperboard substrate with a basic weight of 150 to 350 g/m2 and a thickness of about 50 μm of 8 to 20 g/m2 PE liner.

Figure 1 shows the basic design elements of the coffee cup: the cylindrical wall portion (a) along the vertical lap joint (b), connecting the end edges (c) and (d) (Mohan and koukoulas 2004). In this design, single-sided PE coated plate forms a single wall cup. The outer layer (top layer) can be coated to enhance printability and thermal sealing. The end edges are fixed to each other using traditional methods, usually melt bonding (hot air or ultrasonic).

The paper cup also includes a circular piping (f) and a separate circular bottom part (E), which is connected and heat sealed on the side wall. The latter is a thicker caliper than the bottom cardboard base. Sometimes, both sides of the bottom cup holder are coated with PE for better sealing. Figure 2 is a photo of a paper coffee cup made of extruded stone based PE coating.

Figure 1. The design elements of the single wall paper cup were adapted from Mohan and koukoulas (2004)

Advantages of automatic paper cup making machines

1. The machine is equipped with PLC control system and sensor fault detection. When the machine fails, it will automatically stop working, which greatly improves the operation safety and reduces the labor cost.

2. The whole machine adopts automatic lubrication system to make all mechanical parts work more smoothly.

3. More efficient and higher performance.

4. By changing the mold, it is easy to make cups of different sizes.

5. Equipped with automatic cup feeding system and counter.

6. Excellent return on investment.

7. The industrial market is growing.

8. Ensure a higher level of productivity

In the following video, you can see how paper cups are made through the best paper cup machine. You can see that the program and function of the paper cup machine are so smooth and elegant. It uses innovative technology to make paper cups in a very smooth way and at a fairly fast speed.

Conclusion

As a manufacturer of cup machines, we have seen many advantages of highly automated paper cup machines. When you want to incorporate these technological miracles into your production operations, please check GTMSMART machines. We are one of the largest manufacturers of full-automatic paper cup making machines in China, and our rates are incomparable. We provide first-class machinery that can quickly meet your large-scale production needs. Check our product line and you will find a variety of high-performance options to meet your needs.

Single PE Coated Paper Cup Making Machine HEY110A

Paper cups produced by HEY110A single PE coated paper cup machine can be used for tea, coffee, milk, ice cream, juice and water.

Automatic Paper Cup Forming Machine HEY110B

Automatic disposable paper cup making machine mainly for the production of variety of paper cups.

High Speed PLA Paper Cup Machine HEY110C

High speed paper cup machine can be used for tea, coffee, milk, ice cream, juice and water.

People’s demand for these commodities has risen sharply in both metropolitan and countryside regions. It is believed that there is considerable industrial growth in the paper cup manufacturing industry in this field. Due to the obvious high demand and supply shortage, now is the best time to start your paper cup manufacturing business.

Post time: Oct-09-2021