Keeping up with the low-carbon theme, the production of degradable packaging machines came into being.

As the concept of low-carbon environmental protection has become the main theme of society, many fields are practicing low-carbon environmental protection, and the same is true in the field of packaging materials.

In order to control the pollution caused by plastic waste to the ecological environment, degradable plastics came into being and became a research and development hot spot of global attention. In addition, rising energy costs are also laying the groundwork for the success of bio-plastics in the market. Bio-plastics refer to plastics generated under the action of microorganisms based on natural substances such as starch. It is renewable and therefore very environmentally friendly. Not only that, its adaptability to the body is also very good, and it is expected to be used in the production of medical products such as postoperative sutures that can be absorbed by the body.

Bio-plastics can be used to reduce the oil consumption in the production of plastics; Bio-plastics do not contain toxic substances such as polyvinyl chloride and phthalates. The impact of these toxins on health has been widely concerned. Some countries and regions have decreed to prohibit the addition of phthalates in toys and baby products; The development of bio-plastics is obtained from pure plants, which contain a large amount of starch and protein, which is also the main source of acrylic acid and polylactic acid in bio-plastics. The acrylic acid and polylactic acid extracted from plants are produced into biodegradable plastic materials through various processes, which avoids pollution and damage to the environment to a great extent, This is the incomparable advantage of traditional plastics.

GTMSMART specializes in plastic manufacturing machinery for many years. Machine innovation For your healthier & our greener world!

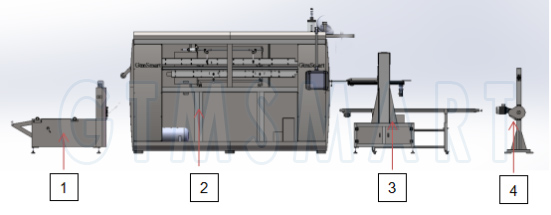

HEY11 Biodegradable Disposable Cups Making Machine

1.Auto-unwinding rack:

Designed for overweight material by using pneumatic structure. Double feeding rods are convenient for conveying materials, which not only improves the efficiency but reduces the material waste.

2.Heating:

Upper and down heating furnace, can move horizontally and vertically to ensure that the temperature of the plastic sheet is uniform during the production process. Sheet feeding is controlled by servo motor and the deviation is less than 0.01mm. The feeding rail is controlled by closed-loop waterway to reduce the material waste and cooling.

3.Mechanical arm:

It can automatically match the molding speed. The speed is adjustable according to different products. Different parameters can be set. Such as picking position, unloading position, stacking quantity, stacking height and so on.

4.Waste winding device:

It adopts automatic take-up to collect surplus material into a roll for collection. Double cylinder structure makes the operation easy and convenient. The outer cylinder is easy to take down when the surplus material reach a certain diameter, and the inner cylinder is working at the same time. This operation will not interrupt the production process.

Conclusion:

When you wish to include these technical marvels into your production operations, look no further than GTMSMART Machines. We offer first-class machinery that can quickly meet your mass production needs. Check out our product line and you’ll find a variety of high-performance options to choose from to suit your needs.

Post time: Jan-21-2022