What Is The Characteristics Of Plastic Thermoforming Processing?

1 Strong adaptability.

With the hot forming method, various parts of extra large, extra small, extra thick and extra thin can be made. The thickness of the plate (sheet) used as raw material can be as thin as 1 ~ 2mm or even thinner; The surface area of the product can be as large as 10m2, belonging to semi shell structure and as small as a few square millimeters; The wall thickness can reach 20mm and the thickness can reach 0.1mm.

2 Wide range of applications.

Due to the strong adaptability of hot formed parts, it has a wide range of applications.

3 Less equipment investment.

Because the thermoforming equipment is simple, the total pressure required is not high, and the requirements for pressure equipment are not high, the thermoforming equipment has the characteristics of less investment and low cost.

4 Convenient mold manufacturing.

The thermoforming mold has the advantages of simple structure, low material price, easy manufacturing and processing, low requirements for materials, and convenient manufacturing and modification. It can be made of steel, aluminum, plastic, wood and gypsum. The cost is only one tenth of that of injection mold, and the product design changes quickly, which is suitable for the production of small batch parts.

5 High production efficiency.

When multi-mode production is adopted, the output per minute can be as high as hundreds of pieces.

6 High waste utilization rate.

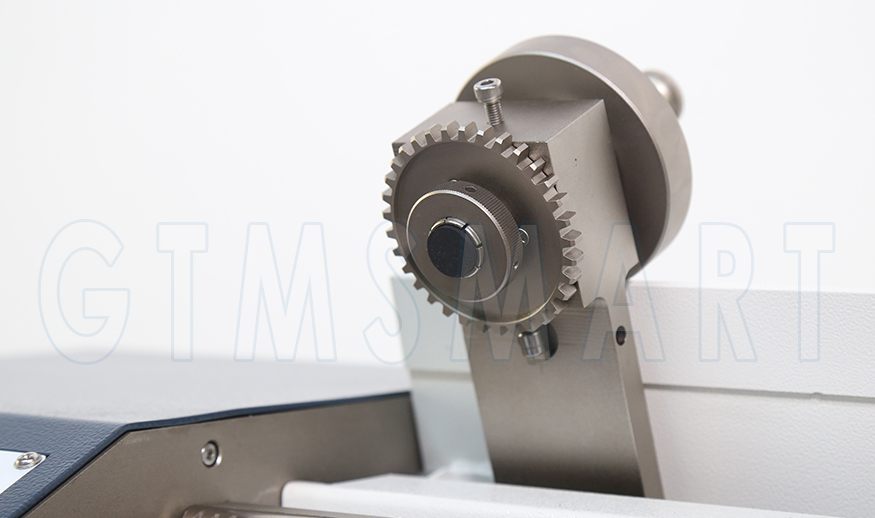

GTMSMART is deeply involved in thermoforming machinery manufacturing, with mature production lines, stable production capacity, high-quality skilled CNC R&D team, and a complete after-sales service network. Welcome to consult.

Post time: Feb-19-2022